EnOcean Sensors Enable Wireless IoT Monitoring in Heavy Industrial Plants

February 14, 2025

Sensor networks are essential for advanced IoT monitoring and control systems but integrating such sensors into industrial plants poses challenges such as wiring, power supply, and maintenance.

To address these issues, Sumitomo Heavy Industries Inc. partnered with Nifco Inc. to conduct a demonstration test of EnOcean sensors in a heavy-duty industrial environment. These wireless sensors, which are powered solely by energy harvesting from their own environment, therefore requiring no batteries, were installed in a system combining multiple communication technologies. By using waterproof EnOcean based multi-sensors with reinforced antennas, Sumitomo aimed to validate the system’s durability and communication stability for practical applications.

Purpose of the Demonstration Test

Sumitomo launched a plant operation support service recently, but in order to further support customers with advanced data analysis, not only data from machinery but also from the surrounding environment are required. However, adding sensors in large industrial plants is often cost-prohibitive due to challenges like wiring, power supply, and maintenance requirements. EnOcean sensors, with their wireless and energy-harvesting capabilities, offer a unique solution. Therefore, this demonstration test aimed to determine whether stable data collection is feasible in outdoor, large-scale, and heavy-duty environments.

System Configuration and Testing

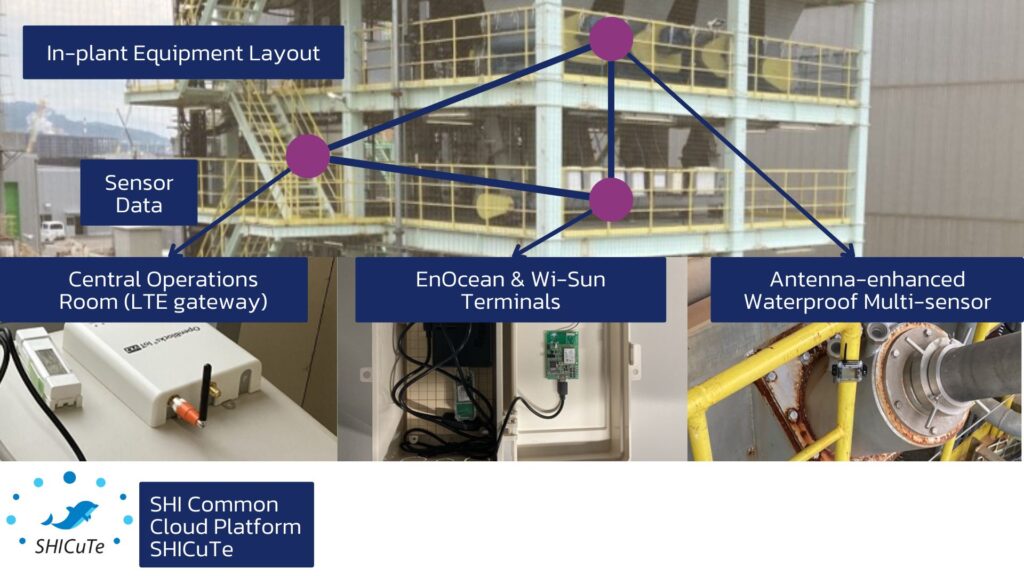

To ensure reliable data collection from EnOcean sensors within multi-level metal structures, Sumitomo deployed a mesh network of Wi-Sun terminals at various levels. These terminals collected data from the sensors and transmitted it via an LTE gateway in the central operations room to Sumitomo´s secure cloud platform SHICuTe for monitoring. The system was tested on an operational site for about one week to assess the sensors’ performance and the stability of data transmission.

Results

During the 8-day testing period, the site experienced heavy storms with rainfall exceeding 80 mm/hour. Despite these conditions, the sensors remained functional, with no water damage nor malfunctions reported. Additionally, the mesh network’s multiplexing of observation points ensured no data loss throughout the test.

Future Development

Industrial sites require significant energy of which a significant amount can be wasted. This presents a high-potential opportunity for EnOcean technology. Moving forward, Sumitomo plans to expand the range of heavy-duty sensors and conduct further demonstration tests to advance the practical application of EnOcean in large-scale industrial settings.